Posted on June 3, 2024, 3:44 pm By admin

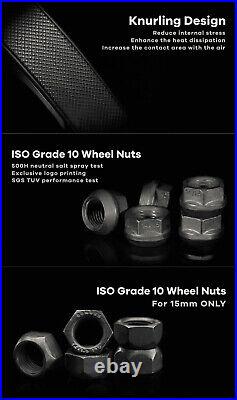

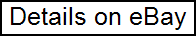

Titanium Wheel Lug Bolts. Aluminum Wheel Lug Bolts. Aluminum Wheel Lug Nuts. 2 15mm BONOSS Hubcentric Wheel Spacers 5×114.3 64.1 for Tesla Model 3 SR+ 2018+. 2PCS TOYOTA 1 THICK HUB CENTRIC WHEEL SPACERS LAND CRUISER PRADO TACOMA TUNDRA. 20 SCM440 Steel Wheel Lug Bolts Nuts 15×1.25 60mm For Mercedes GLE GLS V167 X167. HUBCENTRIC LEXUS WHEEL SPACERS 5X4.5 GS350 IS250 IS350 SC430 – 2X 15MM + 2X 20MM. BONOSS WHEEL SPACER SPECIFICATIONS. ISO Grade 12.9. 15mm(0.59 inch). Cone Lug Nut Grade. Lug Nut Head Hex. Reports by TUV ISO. Global Pioneer Active Cooling Technique, Safer. Forged AL6061-T6 with Tensile Strength? 310 Mpa, Safer. ISO Grade 10 Nuts with BONOSS Engraved, Strength? 1110 Mpa, Safer. ISO Grade 12.9 Studs with BONOSS Engraved, Strength? 1220 Mpa, Safer. Customized Only in 1-3 Days, OEM/ODM Available, More Professional. Over 66 Test Reports by TÜV Certificated, More Professional. For a better shopping experience, it is important to measure the fender gap and confirm thickness before purchasing. Our friendly customer service will help you to solve any question. If the thickness of the wheel spacer is smaller than the length of the original studs, the rims used must allow for small hockets in the mounting surface of the rim. If using rims without enough hockets, the stock studs should be shortened so that they do not extend beyond the thickness of the spacer. Are BONOSS Jeep wheel spacers safe? Wheel spacers are just the automobile accessories installed between the assembly hub and wheel, the wheel lugs apply a clamping force to secure the spacer and wheel to the vehicle hub. Just like wheels, tires, and brake systems, as long as you use high-quality wheel spacers and install them properly, they are safe. BONOSS is always concerned about safety. Take the 5×114.3 wheel spacers as an example, we use forged AL6061-T6 material (tensile strength? 310Mpa), modern CNC machining by 0.02mm tolerance, the multi-stage hub centric design fits the wheel hub better. Meanwhile, the matching wheel studs adhere to ISO standard grade 12.9, and ISO standard grade 10 lug nuts, all of our products have got more than 50 TUV authoritative test reports. Compared with those cheap casting wheel spacers, BONOSS forged active cooling wheel spacers are safer, higher performance, and more professional in design. We believe more professional production offers more value for customers. Why do I need hub centric wheel spacers? What’s the difference between BONOSS multi-stage hub centric wheel spacers and others hub centric? Hubcentric wheel spacers offer a better system of support and stability. They are designed to make a snug connection between the wheel and vehicle hub, reducing the high-speed vibration and ensuring safer driving. Compared with an ordinary hub centric. BONOSS uses the multi-stage hub centric design, which means that multi-stage hub-centric can make the spacers more closely fitted to the wheel hub, greatly reduce the vibration of high-speed caused by the inaccurate hub centric. Besides, they can also be used to change the center diameter of your car, making it possible to install wheels with different center diameters to your vehicle properly, transforming lug centric wheels into hub centric wheels. What is the performance of the bolts and nuts used with BONOSS active cooling wheel spacer? Why is there a BONOSS engraved on it? The wheel studs of the wheel spacers produced by BONOSS are made of JIS SCM440 steel. Wheel lug studs made of forged SCM440 alloy steel have many outstanding characteristics, such as high-strength, wear resistance, excellent toughness, and impact resistance. It also has the advantages of good ductility and high-temperature stress resistance, structural stability, fewer harmful elements, and fewer surface defects. It has reached ISO standard grade 12.9, tensile strength? 1,220Mpa, ultimate tensile load? 152,000N, hardness (HV)? 395, NSS? 500H. The matching nut is made of 40Cr material, after high-strength forging, in line with ISO international standards Grade 10, proved that the load is? 1110Mpa, the hardness (HV) is? 349. They are enough to cope with the fierce racing competition. For normal driving, they can easily withstand thousands of strong shocks. BONOSS insists on producing professional forged wheel spacers and provides wheel spacer far higher than the industry’s safety and professional standards. How does the “active cooling” function works on my wheel spacers? Through the rotation of the wheel spacers, the external cold airflow takes away the internal heat through the active cooling grooves, so as to achieve the purpose of active cooling, improve the braking efficiency and reduce the risk of driving safety. Installing BONOSS forged active cooling wheel spacers can improve braking efficiency, maintain the brakes at normal temperature, and ensure your driving safety. The production cost of BONOSS “active cooling” technology is almost the same as that of traditionally designed wheel spacers. You don’t need to pay extra, that’s why we say that BONOSS forged active cooling wheel spacers are particularly price-friendly. BONOSS wheel spacers provide more additional functions, higher safety, higher performance, more professional design, and better installation experience. What are the benefits of the knurling design on my wheel spacers? The knurling design can enhance the aesthetics of the wheel spacers by introducing an attractive pattern to the side surface. In addition to aesthetics, there are practical features. Knurling patterns can enlarge the side area so that it can contact more air, boost the heat dissipation effect, and reduce the internal stress caused by machining. That means improving the performance, strength, and durability of the wheel spacers. BONOSS aims to provide wheel spacers with more additional functions, safer, higher performance, more professional design, and better installing experience, that is why we insist on independent manufacturing and continuous optimization of the design. How thick wheel spacers do I need? Here is a simple method: use a straight edge such as a metal ruler, place the straight edge on the outermost part of the rims where the wheel comes closest to the fender (preferably the top), then, measure from the outside wheel to the straight edge. This distance is the size spacer you will need to achieve the look that flushes or nearly flushes with the fender line. Can I customize the wheel spacer with different thicknesses and data? How soon can it be customized? BONOSS has an independent design customization department and customized production line, so custom-sized wheel spacers can be completed within 3-10 days as soon as possible. Commonly used 1-inch wheel spacers stocks are sufficient, if you need wheel spacers with irregular thickness or torque, to install wheels with different data. BONOSS customized wheel spacer will be your best choice. BONOSS provides customized services of unconventional thickness, the thinnest thickness is 0.1 inches (3 mm), the thickest thickness is 6.4 inches (160 mm). Why BONOSS choose and TUV to test the quality of the product? And TÜV Rheinland as the world’s famous testing service companies, standing for safety and quality. To earn customers’ trust, which is also our confidence in product quality. BONOSS has fully passed over 66 ISO standard, TÜV authoritative tests, and all achieved excellent scores. BONOSS forged grade 12.9 extended wheel bolts have passed the 2,000,000 times limited life range test without damage, tensile strength? 1,282Mpa, ultimate tensile load? 152,000N, hardness (HV)? 395, NSS? 500H. By these authoritative test reports, BONOSS truly achieves the quality and professionalism expressed in the form of data and truly guarantees safety. We believe high standard quality management, together with authoritative certification reports is the best way to meet customer and regulatory requirements. Remove original wheel bolts and wheel. Put BONOSS Wheel Spacer on hub of car (where hold the wheel) Please ensure that the spacer is fully seated and flush with the hub. Put wheel onto the spacer and match the wheel & spacer bolt holes and mounting hole. Insert new longer BONOSS wheel bolts. Carefully hand turn bolts making sure that they spin in easily and fit well. Repeat above step with the bolts left. Use hand wrench to tighten extended bolts in a star pattern. Spin the wheel and tire to check whether it cause any noise or interference or not before fully tightening bolts. Use torque wrench set with wheel manufacturers’ specifications to tighten the longer bolts in a star pattern. More and more customers believe in BLOXSPORT’s profession, so choose us. BONOSS have been specializing in manufacturing the wheel parts for 10years. We supply wheel nuts/boltsLocking/Classic… , wheel spacers3mm-120mm, 1 inch etc. , custom wheel adapters 5 lug to 5 lug; 4 lug to 4 lug; 5 lug to 6 lug;6 lug to 8 lug… We refuse to use the wheel spacer made of casting aluminum and the bad quality bolt/stud, lug nut. We insist in using the forged aluminum alloy and high quality bolt/stud, lug nutpassed the 1 Million times Fatigue Test, etc. We always insist on four concept respectively. Insistence on the service philosophy that safty is No. 1 and creating the value for our customers. Insistence on designing and producing by ourselves in order to make sure the our product’s stability of the quality and reliability. Insistence on the test from the third party. Insistence on requiring ourselves to live up to the highest standard among our rivals in order to make sure that our product will be in the perfect condition in our customer’s hand (not only the best quality but also there’s no scratch on our products which has been sent to our customers). (4) 40mm Mercedes G Class G Wagen G Wagon G Force Wheel Spacers Adapters 5×130. 2X 35mm 5 Lug Wheel Spacers 5×120 for BMW X5 E70 F15 (07- 17) Front and Rear. 2X 8mm + Bolts Forged Hub Centric Wheel Spacers for Mercedes W211 W212 W220 W221. 2X 10mm + Bolts Hubcentric 5×120 Wheel Spacers for BMW 3 Series E36 E46 E90 F30.

Categories: 15mm Tags: 15mm, 5x120, adapters, civic, honda, lugs, spacers, studs, type, wheel